A Company Of Quality

MECPRO, Inc. is a precision machining company located in the heart of Silicon Valley. We have been providing high quality precision machining solutions to companies in the United States since 1979.

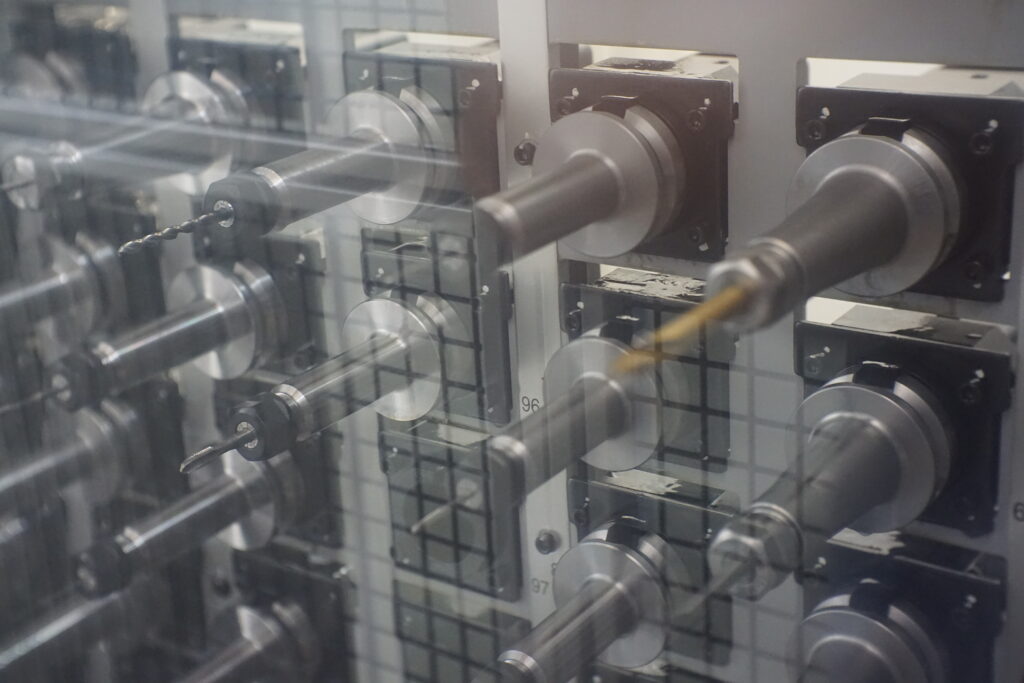

All of our modern precision CNC machines are control serviced to keep them functioning at peak performance and ready to produce parts within the full range of their capabilities.

On-Demand Service

Whether your need is for prototypes, first articles, or full-scale production of precision parts, MECPRO can accommodate your phase of product development without excessive outlays of time or money

We produce both individual parts and sub-assemblies from a variety of metal alloys and plastic formulations, and we never shy away from parts with challenging sizes and configurations.

Our Quality

ISO 9001:2015 Certified

The Standard

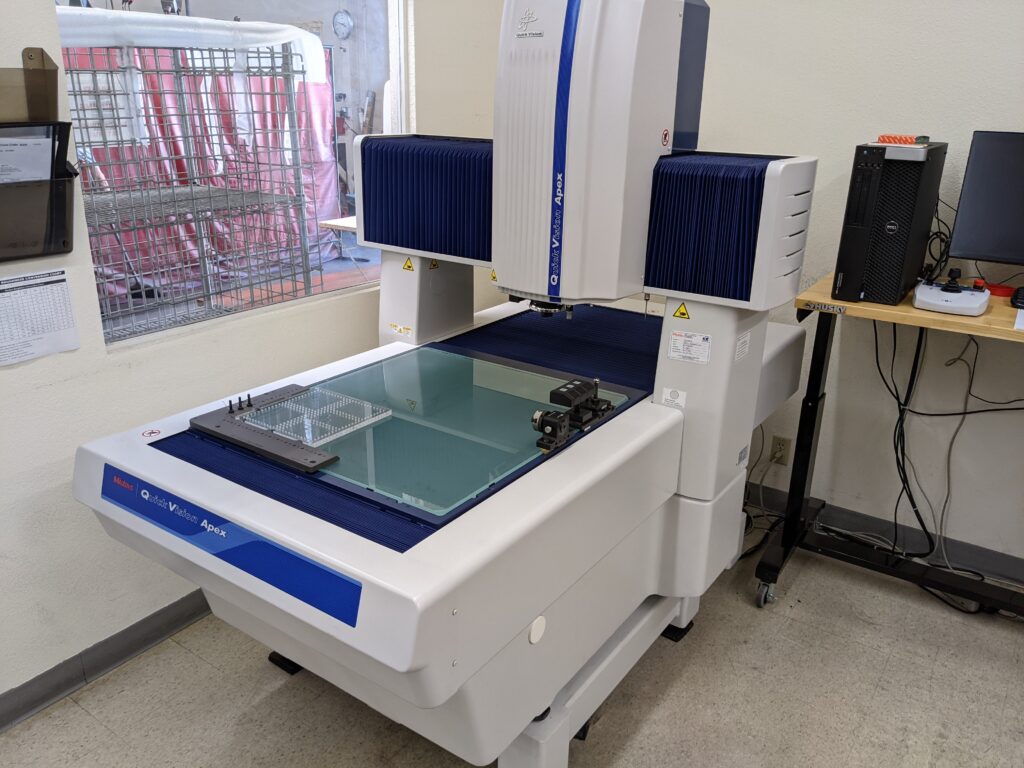

At MECPRO, our commitment to precision extends to our temperature-controlled inspection department. We adhere to a rigorous calibration schedule in strict compliance with the ISO 9001:2015 calibration standard, ensuring that all our gauges and inspection test equipment are meticulously maintained and calibrated. Our calibration process is meticulously traceable to the National Institute of Standards and Technology (NIST), guaranteeing the highest level of accuracy.

Additionally, we take pride in the availability of our ISO Quality Control Manuals, which provide comprehensive documentation of our quality control processes and procedures. These manuals serve as a valuable resource for our team and underline our dedication to maintaining the highest standards of quality throughout our operations.

The Procedure

The backbone of our inspection process is a computer controlled Coordinated Measuring Machine. The related software provides us with continuous inspection throughout the job, from First Article to Final Inspection. Our sampling plan follows ISO Q.O.P. 20-1. In Process and S.P.C. Inspection reports can be made available to suit your company requirements.

CAD-CAM System

Our latest software’s allow for the direct importing of standard drawing files. We also have 5-axis programming capability, with full 3D surface machining.

MILLS:

• 2 Bridgeport Vari Head Vertical Mills with • Digital Readout Computer Systems

GRINDERS:

• Boyer Schultz Surface Grinder

• Optima Drill Grinder

MISC:

• Econoline Bead Blaster

• Roto Finish Tumble Deburr

SEEING IS BELIEVING

One of the best ways to evaluate any operation is by seeing it firsthand. Customers are always welcome at our 15,000-square-foot Santa Clara facility. It’s one of the cleanest operations of its kind in the industry, and we enjoy showing it off.

Call any time and we’ll be happy to arrange a site tour.

EXCEPTIONAL WORKMANSHIP At MECPRO, we believe that even the most advanced facility is only as good as the people running it. That’s why we’ve assembled a staff of highly trained personnel. Our on-going training program ensures that your job is always in the most qualified hands.

MECPRO is a certified supplier with a long record of quality work and exceptional customer service. We continue to satisfy the diverse needs of a wide range of customers, from computer manufacturers to medical researchers, from international corporations to local enterprises.